OCTO TRIO is the unique cooperation and license partner of VKM Plastic who is authorized to make sales & marketing activities in commercial vehicle industry globally.

According to “THE FRAME PARTNERSHIP AGREEMENT” signed by both parties , OCTO TRIO and VKM manage all interior ambulance equipment and device solutions coming from commercial vehicle industry together.

Main responsibility of VKM in this corporation partnership is to make all technical, planning, production and logistic activities professionally. In this corporation, VKM is authorized to make ;

- Vacuum plastic part design by providing customized solutions

- All Research and development construction and documentation activities

- Project milestones that is already been determined by project team

- All planning and production activities

- Quality applications

- Logistic organization

VKM Plastic was established in 2012 in Bursa. Since the day it was founded, it has adopted the principle of making continuous investments that will improve the quality of its products. With its quality the company’s customer portfolio has increased. As of 2019, VKM has started to produce plastic injection molds with its second vertical machining center. Company has 1800m2 production plant.

Production Capability of VKM including;

- Robot Trimming Technology

- Metal Cutting Process

- Plastic Injection Mold Workshop

- 3D Design Capability

- Thermoform Technology

- Ultrasonic Welding

3D Design Capability

VKM using latest version of CAD/CAM software to develop and form products according to our customer requests and projects.

VKM either design the products according to our customer’s data or we gather the data using reverse engineering.

VKM using ATOS 3D optical scanner for this process.

Beside plastic products VKM provides 3D modelling support to our customer.

Metal Cutting Process

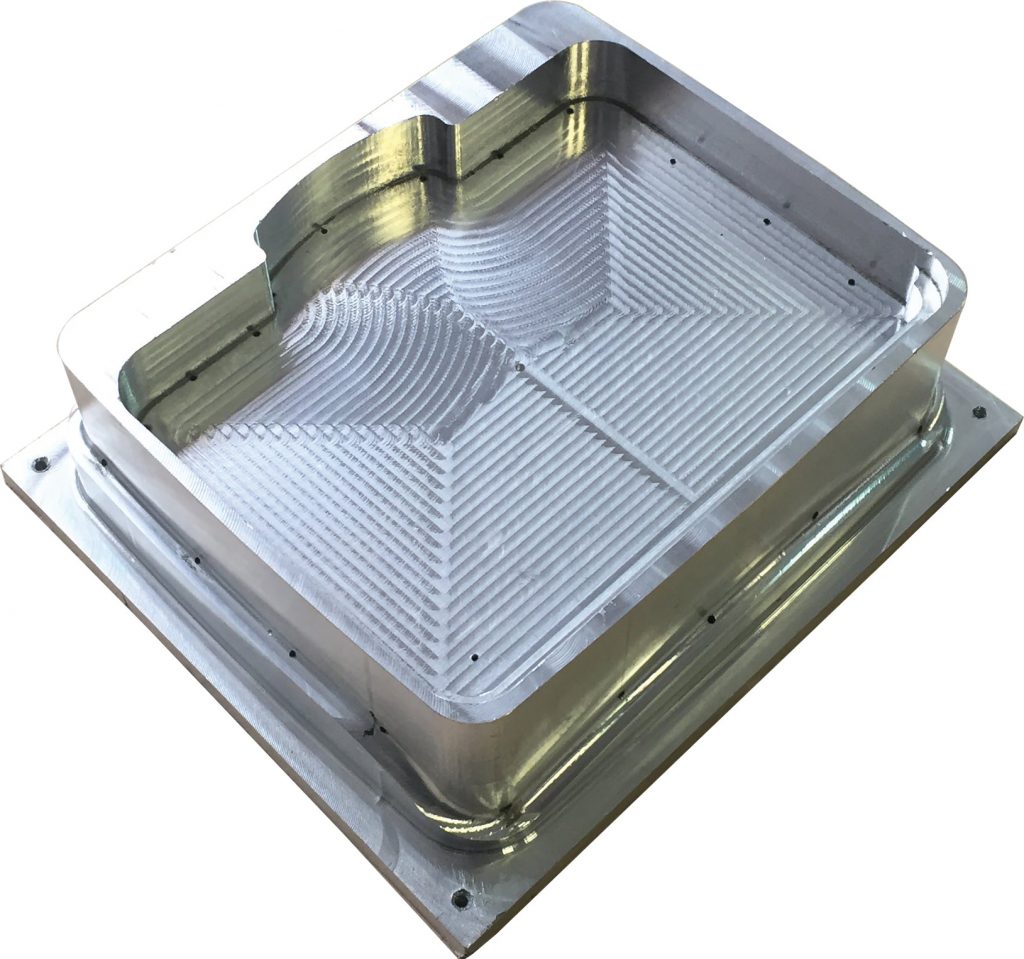

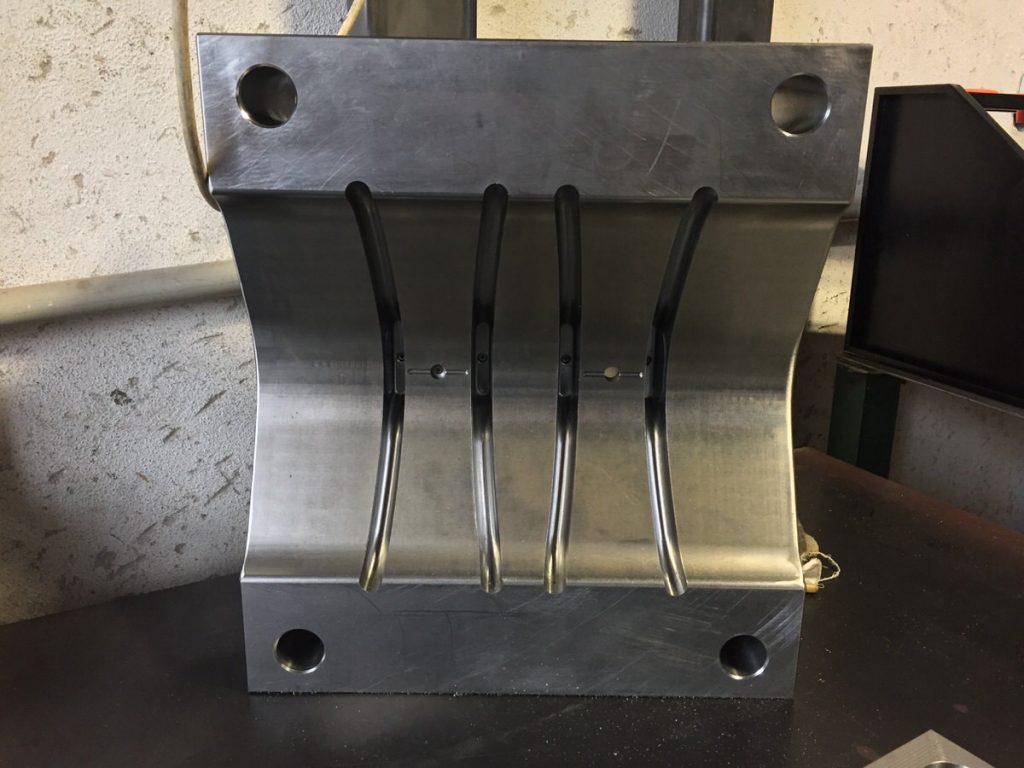

Plastic Injection Mold Workshop

Since beginning of 2019 we make plastic injection molds in our CNC vertical processing center

Robot Trimming Technology

Thermoform Technology

With VKM’s vacuum machinery park we can form up to 6000X220mm size plastic sheets into product.

Ultrasonic Welding

VKM is using Ultrasonic welding for bonding ABS parts if it’s necessary.

This process is done with extra care and the result is successful.